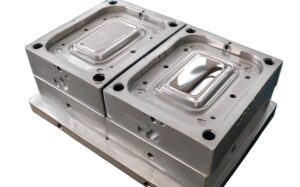

Mould Making

Although mold manufacturing requires a greater investment than tooling designed for prototyping or small series production, it is important to understand the differences between them. Lipu Zhizao uses industry-leading technology and technology to manufacture various molds for you.

Mold Manufacturing Services

|

|

|

|

| Single Cavity Mold | Multi-Cavity Mold | Stack Mold | Two-Color Injection Mold |

| Optimize small-batch plastic production with our cost-effective single-cavity injection molds, providing greater control and precision throughout the manufacturing process. | Efficiently produce multiple plastic molded parts with our high-quality multi-cavity molds. These molds optimize cycle times and reduce unit costs, resulting in increased productivity and increased parts per cycle. | Improve molding efficiency with innovative laminated molds made by Lipu. Our design reduces part costs and allows multi-component assembly in a single cycle with customizable cavity configurations | Efficiently mold two materials using our two-color injection mold, combining soft and hard plastic in a seamless process to save costs and reduce assembly steps. |

Mold Material

|

|

|

| Chisel Tool Steel | Stainless Steel | Aluminium Alloy |

| P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 | 420, NAK80, S136, 316L, 316, 301, 303, 304 | 6061, 5052, 7075 |

Business Process

Our Advantages

We are committed to helping you launch and realize your project. We understand that achieving the ultimate vision for our products requires a balance between throughput, strict timelines, logistics and cost-effectiveness.

Our production injection mold services complement our prototype and transition mold services to help you move smoothly into production. Partnering with Saint Rich for mass production, you will enjoy the following benefits:

If you have specific smartwatch needs or concerns, it’s time to speak to one of our Industry Experts. We’re here to answer any questions you may have!

We are the comprehensive enterprise focusing on Die-Casting, Injection Molding, Stamping, CNC Machining and Mold Making

sales02@saint-rich.com

+86 189 333 57957

粤ICP备12000987号